How Advanced Technologies and Software Are Transforming Tensile Fabric Manufacturing

LUCKY-TECH Membranes Pvt Ltd utilizes automated cutting systems, specifically the Swiss-made ZUND machines, for precise fabric cutting. These machines are highly accurate, ensuring millimeter-level precision and perfect panel sizes for their tensile membrane structures. They also employ advanced high-frequency welding from FORSSTROM, Sweden, for strong, error-free welds.

Key aspects of LUCKY-TECH's cutting process:

Key aspects of LUCKY-TECH's cutting process:

Automated Cutting: They use ZUND machines, which are fully automatic and conveyorized, ensuring accuracy and efficiency.

High Precision: The cutting is accurate to the last millimeter, guaranteeing precise panel sizes.

Advanced Welding: They utilize FORSSTROM equipment for high-frequency welding, resulting in strong, error-free welds.

Sealing of Seams: Seams are sealed to prevent gas/air leakage and damage, increasing durability.

Order Management Application

Application / Industries - Tensile

Longevity / Long Life - 15 - 20 years, better than other fabrics in the market

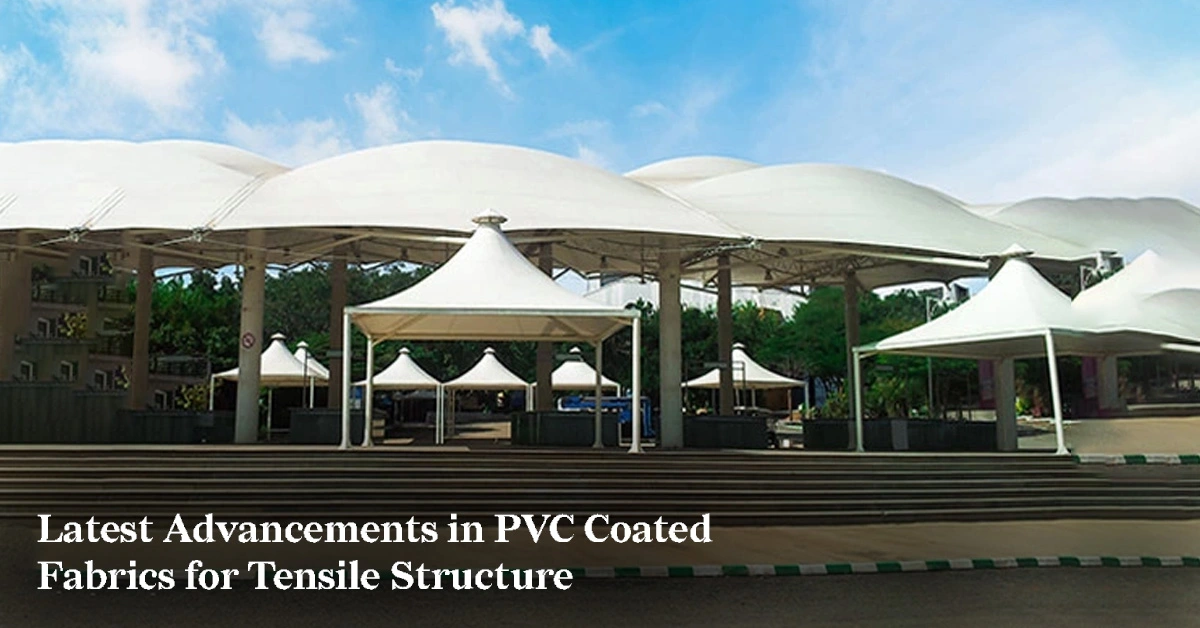

The tensile structures have been used right from ancient times in the form of tents. With the modern advancements in technology, these structures have gained much popularity in the architectural industry. Over the decades, tensile fabric manufacturing has seen drastic changes. Modern-day tensile fabrics are water-resistant, fire-resistant, and UV-resistant. With the cutting-edge technology and advanced software, the tensile fabric manufacturing is evolving faster in both creative and functional ways.

Understanding the potential of the tensile fabrics, the Indian market has seen a growing demand for PVC-coated fabric manufacturers. The role of advanced technologies is changing the standards of efficiency, durability, and quality from the conception of the design to the final installation of fabric structures. One industry leader, LUCKY-TECH Membranes Pvt. Ltd., is redefining what is feasible in tensile membrane manufacturing by utilizing state-of-the-art instruments and techniques. LUCKY-TECH Membranes is one of the leading PVC-coated fabric manufacturers and the PVC-coated fabric suppliers in India. We are a world-renowned firm that has decades of experience in the field of Advanced Technical Textiles / PVC Coated Fabrics. LUCKY-TECH pioneer in lightweight membrane innovation for applications.

Through this blog, we will have a detailed analysis of how advanced technologies and software are transforming tensile fabric manufacturing.

What is vertical Integration, and how is it important in Tensile Fabric Manufacturing?

The vertical strategy is one of the important strategies followed in the business, in which the company increases its control over several production and supply chain stages. The business handles some or all of these tasks internally rather than depending on outside suppliers or contractors for raw materials, manufacturing, distribution, or installation.

Here is a detailed idea of how the idea of vertical integration affects the tensile fabric manufacturing.

The company does not rely on external suppliers or vendors in vertical integration, everything from the raw material to the finished product. This will greatly help the customization of the products, enhance the production quality, and improve consistency. The ultimate goal of the LUCKY-TECH membranes is to manufacture premium-quality tensile structures with a higher longevity than other fabrics in the market.

These high-quality fabrics are manufactured to withstand the harsh climatic conditions. Through specific weaving, coating, and fabrication processes, contemporary tensile fabrics are ensured to be long-lasting and aesthetically performative, conforming to global quality and safety standards.

Technicity: The intersection of precision and performance

The concept of technicity is very important when it comes to the field of tensile engineering. Technicity often considers how well the technology works and how well we use it. The idea of technicity in tensile architecture is used to denote the technical, material, and process-related attributes that determine the functionality, performance, and design logic of tensile structures. It highlights how engineering concepts, material properties, and construction techniques condition the form and behavior of a tensile system.

In modern times, the tensile fabrics have shown a visible improvement. With the advanced technologies and modern composites, they offer a wide range of characteristics. They include,

Material properties and traits:

With the help of technicity, the PVC-coated fabric manufacturers will have a deep understanding of how the fabric works under tension. Here is where one can understand the longevity of these PVC-coated fabrics. These includes- Elasticity and Plasticity

- Tensile Strength

- Tear Strength

- Weather resistance

- Self-Cleaning properties

Structural Reasoning:

Technicity in tensile engineering describes the technical, material, and process-related features that determine the functionality, performance, and design logic of tensile structures. It highlights how engineering principles, material characteristics, and construction techniques determine the form and behavior of a tensile system.

Only with these qualities can one determine whether the tensile fabrics are ideal for raising long-lasting architectural structures.

LUCKY-TECH’s Automation Edge

LUCKY-TECH looks for innovative solutions for the tensile fabric manufacturing. We are determined to use the smart engineering solutions. This has brought a significant advantage to the industry in fabric cutting and welding. The innovative approach of the LUCKY-TECH membranes has made them one of the reliable PVC-coated fabric manufacturers in the industry. We have a state-of-the-art Engineering setup to European standards. Engineering Software from TechNet Germany.

Precision Cutting Utilizing the ZUND system

What is the ZUND system? The ZUND system is nothing but a high-precision digital cutting machine developed in Switzerland. At LUCKY-TECH, the fabric is cut using this latest conveyorised equipment, which ensures precision to the last millimeter. These machines are fully automatic. With this advanced technology, the wastage is reduced, and you can get the exact design that you have customized. Another important advantage is that it reduces the stage due to human error, and thus, a cost-effective technology to approach. From thin film to thick composites, it can handle a wide range of materials. With this advanced technology in the fabric engineering, the precision, efficiency, and productivity are improved, especially for a large-scale production like LUCKY-TECH.

Automated high-frequency Welding with FORSSTROM

FORSSTROM is a highly advanced and sophisticated welding equipment from Sweden. This automated high-frequency welding machine uses HF energy to create strong and durable welds in thermoplastic materials like PVC and PU without the need for external heat sources. The machines offer error-free welds, ensuring the weld strength, which is almost equal to the fabric strength. One of the major advantages is that with this advanced technology, the labor costs are significantly reduced.

Importance of Forsstrom in Tensile Fabric Manufacturing

In tensile architecture, where fabric panels must be precisely joined to maintain shape, tension, and weatherproofing, Forsstrom machines offer several advantages:

Reliable Seam Strength:

Essential for structural integrity under load.Weather and UV Resistance:

Seam quality matches or exceeds the base material's durability.Aesthetic Finish:

Clean, smooth welds without bulky stitching or adhesives.Scalability:

Suitable for small custom projects or mass production.

Sealing of Seams

At LUCKY-TECH, we seal the seams, which prevents entry of Gas into the base Polyester fabric- thereby preventing damage & increasing durability. This also prevents gas/air leakage/loss.

Redefining Tensile Fabric Manufacturing: Everything you need to know about 3D Modelling and Simulation

In the past, architects used to sketch the tensile structures on paper before they started constructing. But today, with the help of advanced technology, you can design the 3D model of the tensile structure. This will give you a clear image of the structure you are planning to construct. This will also greatly enhance artistic freedom.

The traditional way of tensile design requires more manual energy and time. But with the help of the 3D modelling and Simulation software helps in the accurate calculation without spending too much. With the advanced technology, the machine instructions are generated directly from the CAD designs.

Final Thoughts,

Contemporary technology has transformed tensile fabric architectural design as well as construction techniques by creating more efficient, sustainable, and creative results. The success of architectural marvels through tensile fabric structures largely relies on technological innovations, which encompass sophisticated design techniques along with high-performance materials, creative fabrication techniques, along intelligent technologies.

LUCKY-TECH provides you with a distinctive collection of top-quality tensile membranes for the construction of these functional structures, which are a great alternative to conventional constructions. Our tensile design fabrics are ideal for both open and closed buildings such as shopping malls, airports, and stadiums. Through this blog, we will walk you through the benefits, materials, and applications of these tensile fabric roof designs.

Get Your Free Quote Today!

Tell us about your project needs and we'll provide a custom quote tailored to your specific requirements.